The Essential Role of Packers in Professional Glazing Projects: A Trade Perspective

In the world of professional glazing, the smallest components can play the most crucial roles. Packers are an excellent example—these seemingly simple devices are essential for the stability, efficiency, and longevity of any glazing installation. From ensuring precise alignment to maintaining structural integrity, packers provide essential support to glazing systems across various types of projects.

In this article, we’ll explore why packers are indispensable in glazing, dive into their specific functions, discuss best practices for using them, and outline how trade professionals can make the best choices for their unique project requirements.

What Are Packers in Glazing, and Why Are They Important?

Packers, also known as shims or spacers, are small, flat, plastic or rubber pieces placed between glass panels and their supporting frame. They serve a straightforward yet critical function: to create an even gap that keeps the glass stable within the frame, while distributing weight and preventing stress on the glass.

Packers help ensure that glazing panels remain fixed in place, with even load distribution that prevents cracking or movement over time.

The importance of packers lies in their ability to:

- Protect the Glass by cushioning it from direct contact with the frame, reducing the risk of cracks.

- Ensure Precise Alignment by allowing fine adjustments that lead to a polished and professional finish.

- Maintain Structural Stability by distributing weight evenly and avoiding points of stress.

- Improve Durability by preventing direct contact between materials, which can lead to damage or wear over time.

Types of Packers and Their Applications

There are various types of packers used in glazing, each with unique properties that make them suited to specific applications. Here are some of the most common types:

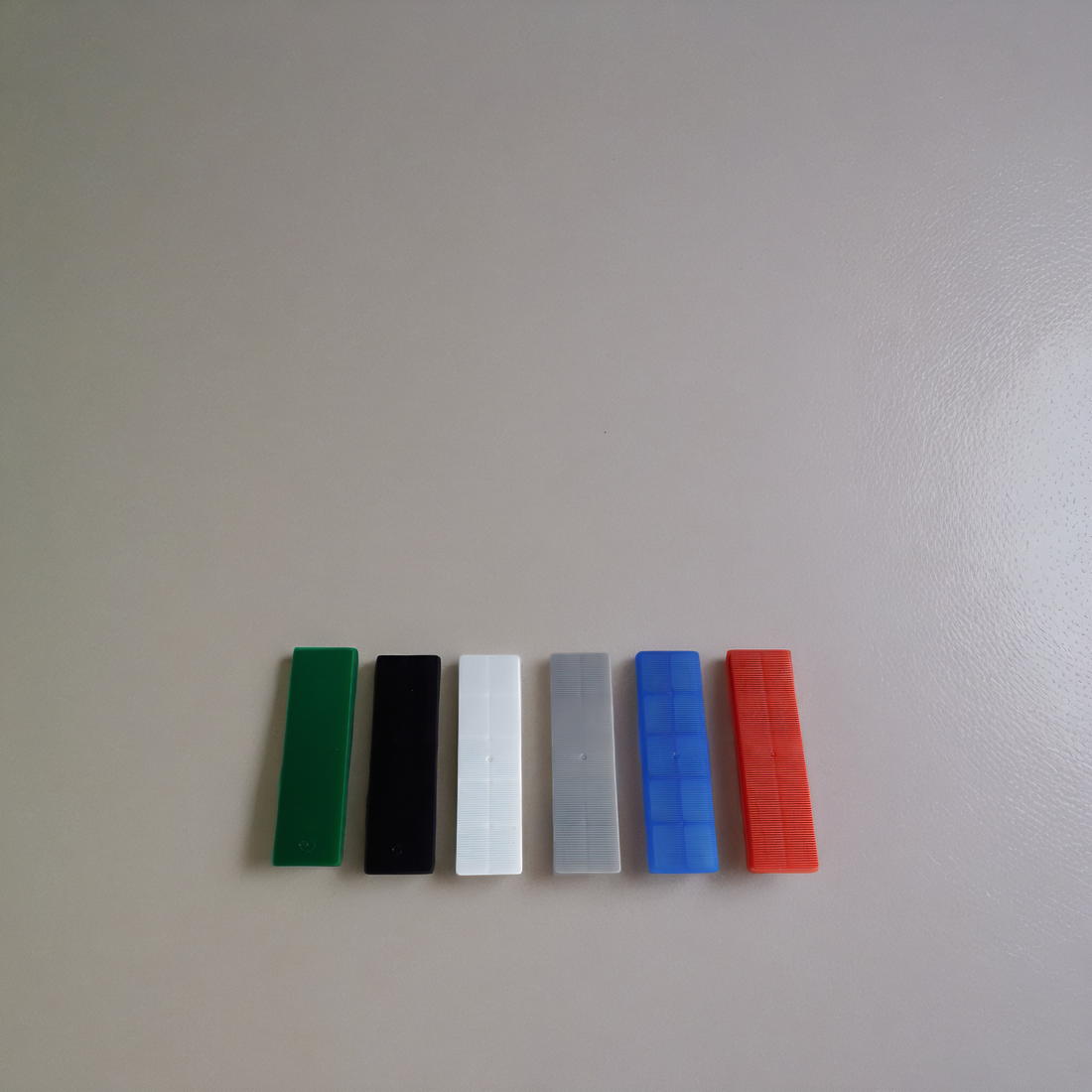

- Standard Flat Packers: Ideal for general use, these packers come in multiple thicknesses and colours to help professionals distinguish between sizes quickly.

- U-frame Packers: Designed for framing applications, U-shaped packers can fit around the edges of glass panels, offering stability and support in three directions.

- Wedge Packers: Used when irregular gaps need to be filled, offset packers allow installers to adjust for uneven spacing, ensuring an even fit.

Best Practices for Using Packers in Glazing Projects

Using packers effectively requires careful planning and attention to detail. Here are some key best practices:

- Select the Right Type of Packer for Each Project

It’s essential to choose the right type of packer based on the glass size, weight, and frame material. Coming in a range of widths and thicknesses flat glazing packers have evolved from 24mm up to 32mm widths and beyond, with the standard 28mm flat packer being the industry bread and butter product.

- Ensure Proper Spacing and Placement

Packers should be placed in strategic positions, typically at the bottom and sides of the glass, to distribute weight evenly. Avoid over-packing, as too many packers can put excess pressure on the glass and lead to cracks.

- Follow Industry Standards for Thickness and Load-Bearing Requirements

Most glazing standards specify the thickness and strength of packers for various applications. Following these guidelines helps prevent issues related to overloading or improper alignment.

- Use Colour-Coded Packers for Efficiency

Many packers are colour-coded to indicate different thicknesses. Using colour-coded packers can help professionals quickly identify and select the right size, improving efficiency on the job. We sell both single colour and mixed size packs to help the busy fitter to get exactly what they need when they need.

- Inspect Packers for Damage Before Use

Inspect each packer for signs of damage, such as cracks or warping. Damaged packers can compromise the integrity of the installation, leading to misalignment or stress points on the glass.

The Long-Term Benefits of Quality Packers in Glazing Projects

Investing in high-quality packers pays off significantly over the life of a project. Here’s how:

- Enhanced Durability: Quality packers are designed to withstand environmental factors, such as temperature changes and moisture, that can weaken lower-quality materials.

- Reduced Maintenance: Properly installed packers prevent glass movement, meaning that the glazing installation will require fewer adjustments or repairs.

- Professional Finish: The right packer not only stabilises the glass but also ensures a smooth, even finish that meets professional standards.

- Compliance and Safety: Using packers that meet industry standards guarantees that the glazing installation is compliant with safety regulations, protecting both the building and its occupants.

Final Thoughts

Packers may be one of the most overlooked components in a glazing project, but they are crucial to the overall success and longevity of the installation. By understanding the role of packers, choosing the right types - did we mention we make all our packers here in the UK - and following best practices, trade professionals can ensure that their glazing installations remain safe, stable, and visually appealing for years to come.

Packers, though small, truly embody the saying that “the whole is only as strong as its parts.” For any professional in the glazing industry, selecting quality packers and using them correctly is a key step towards delivering high-quality, durable installations.